The Best Guide To Masterbatch

Wiki Article

Some Known Factual Statements About Masterbatch

Table of ContentsThe Masterbatch PDFsMasterbatch Can Be Fun For EveryoneMasterbatch Fundamentals ExplainedWhat Does Masterbatch Do?

The cooled down blend, might be described a tempered mix, is then strengthened by cooling down on a dimpled cooled roller E where the strengthened blend is scraped and the fragments are taken by a conveyor belt F to a milling gadget G where it is grated or ground to form flakes or prills of the desired dimension.

The cooled blend, may be called a solidified mix, is after that strengthened by cooling on a dimpled cooled roller E from which the solidified blend is scratched as well as the particles are taken by a conveyor belt F to a milling device G where it is milled or ground to create flakes or prills of the desired dimension.

As the process specified herein permits using a fluid pigment and after that solidified enables a means of having the homes of a liquid pigment in strong form which can be utilized in an even more individual friendly methods. A common misconception for instance, in a white masterbatch, is that the greater the titanium dioxide content the better the product - masterbatch.

The Of Masterbatch

This can have a cost effects, along with technological. Due to the greater loading and because the titanium dioxide is usually a lot more pricey than the provider, the end product comes to be much more costly with the very same or lower dispersion than with the process detailed here. The procedure laid out here with a 50 % loading, does the exact same, otherwise much better than typically manufactured items with a higher than 50 % loading, consequently resulting in much less use masterbatch.

Because a consistent base provider material is initially created, this can be fed to a number of second blending devices where the ingredients are evenly combined with their own buildings, for instance, one secondary mixing device may be mixing a fluid pigment while an additional might be blending a white colour as well as a third a calcium carbonate (masterbatch).

g. masterbatch. amide and/or metallocene) all can be made use of in this strategy along with combined waxes or waxes combined with polymers or polymer mix. Fischer-Tropsch waxes are preferable as they have numerous preferable residential properties a few of which have extremely high purity being essentially free of any kind of sulphur, nitrogen and also aromatic varieties and also have high normal paraffin content.

Masterbatch - Truths

This stability can impact the colour residential or commercial properties during moulding process and in the final item. Avient masterbatches are normally formulated utilizing the finest quality pigments which allow a reduced enhancement prices, commonly 1%, and exceptional colour stability. This can make them appear a lot more costly than options on the market, yet can reduce the opportunity of issues additionally on as well as therefore be inexpensive.We connect with colored plastics on a regular basis, yet have you ever before wondered concerning the color focuses that bring visual appeal to these see this page products? To give colors to the polymers, pigments or masterbatches are used.

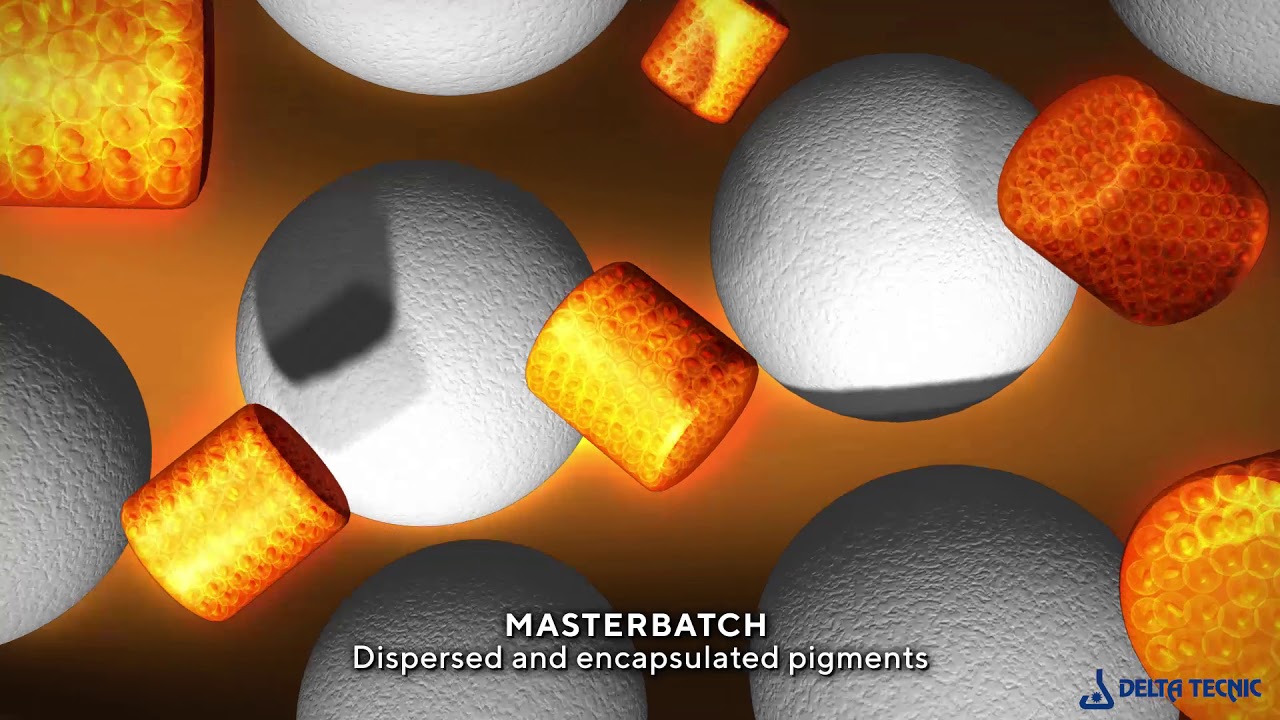

Masterbatches, on the various other hand, are more sophisticated. They are encapsulated by a polymer as well as function particular concentrations of ingredients and pigments. Both pigment and also masterbatch are used for tinting polymer items. However, suppliers tend to favor masterbatch. Listed here are ten sensible reasons to select masterbatch over raw pigments.

Shade focuses can be easily handled during the production process when masterbatch is favored over pigments. There is a high risk of pigments ending up being air-borne throughout the production process.

Getting The Masterbatch To Work

This enables for the end product to have superb shade distribution. Pigments, on the various other hand, do not disperse well on its own. It is simple to match the binding representative made use of within the masterbatch to the polymer for a much better melting process. The quantity of pigment housed in a masterbatch is much less.

Report this wiki page